Tonight after refitting the rear subframe on my Wife’s mini I thought I’d move the engine for the Sabre into the engine bay.

This necessitated fitting the billet sump Andy had supplied with the big box of bling I collected earlier. After the usual fitting of modified pickup and baffle plate I had the sump fitted. Interestingly the is one of Andy’s third generation sumps and consists of a second bit that is bolted to the main sump pan to act as the oil reservoir. This means that you can position the oil drain plug in any orientation. Also I added a tab washer to the mounting bolt near the plug so that I can lockwire it in place.

Of course the main reason for this is to give the engine a flatish sump to sit it on the floor in the engine bay.

So out came my trusty engine crane and after a bit of jiggling and removing of ancillary components, I manged to get it to sit reasonably in the engine bay. One of the design features of the Sabre, is that it has equal length driveshafts and consequently a center mounted diff. Of course this means that the whole engine is offset to the drivers side as the output sprocket is on the left of the engine. I remains to be seen what this does to the corner weights and handling.

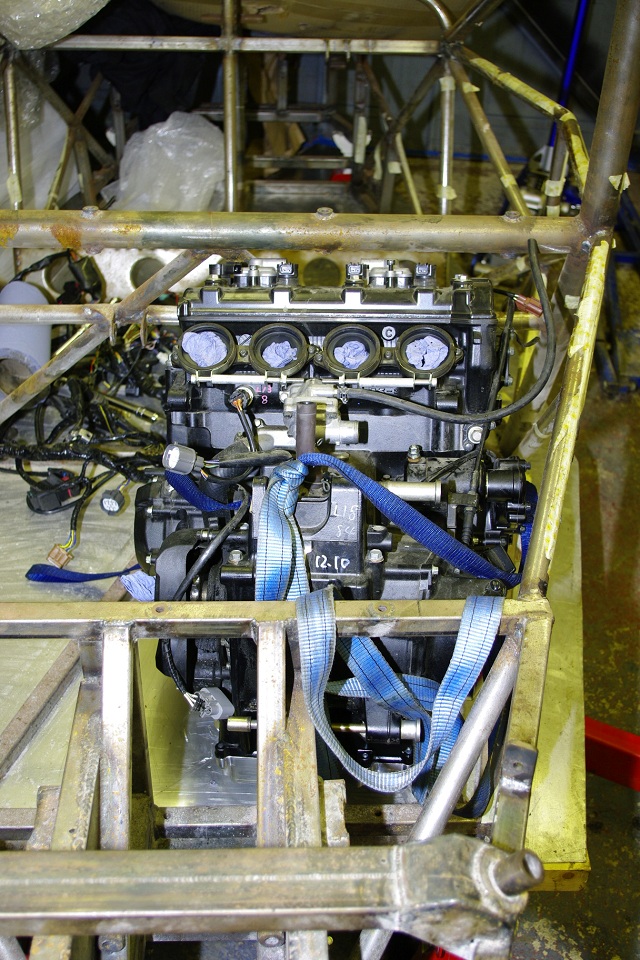

Anyway here’s a pic of the engine loosely in place.

With the main cockpit now empty of engine, I of course, climbed in and made “brumming” noises. The cockpit space really is huge, I may even need a booster cushion.

I then spent a few minutes identifying the various sensors, on the lump and removing any aftermarket rubbish. This engine has plainly been owned by someone who wanted to get his bike to perform, as I think its been fitted with a non standard big bore exhaust, the sump pan has been ground down to accommodate it, and some of the stick coil leads have aftermarket pick ups on them to drive some form of power commander. I’m going to need to go through this loom very carefully.