Hurrah, one end of the car is complete.

I thought I’d post a of picture of what I’ve been up to this week.

I thought I’d post a of picture of what I’ve been up to this week.

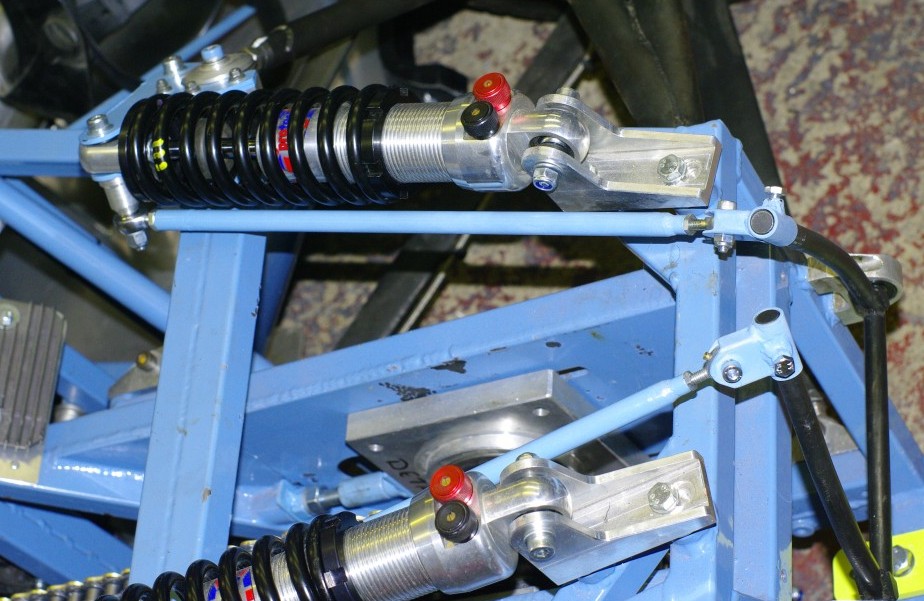

Basically I’ve been building the rear anti roll bar links and spacers. The Links are turn buckles with LH and RH threads at each end to allow for adjustment. The Bar ends are M6, and the damper ends are M8 because that is the bolt size that goes through the damper. At the damper end you can see some conical Ali spacers that I spun up on the lathe. These stand off the link far enough from the bell crank to clear the springs, and hopefully are wide enough at the base to ensure no undue flex due to the stand off distance.

Overall the clearances are tight, but the ARBs have a good 50mm of adjustment on the bars, and I’ve removed the springs and run it through its full range of movement and it all seems fine. Now onwards and upwards to the front ones, which should be much easier to make, as the clearances are nowhere near as tight.

You might notice that the ARB itself has some bends in the actuating arms. Andy supplied the bar with straight end levers. I had to adjust the bar using a big vice, a long lever and some brute force and ignorance, in order to make sure the link rods clear the damper bases throughout their range of motion, and with the link ends at the lower limit of their adjustment.

There is only question remaining at this end of the car. At full droop the wheels just foul the bodywork. This may be because the movement of the bell cranks now means that the push rods are slightly too long even though I have adjusted them to be as short as possible (remember the push rods control ride height at full droop). I’ll check this out once the car is complete as part of the suspension setup, and if necessary either trim the existing ones or knock up a couple of new ones. I have the bits so it wont take long…. which is good as I now have about 12 days before the first test.